|

Fuses and Fusing

Fuses are a necessary element of power supply design.

They serve to protect both the user and the amplifier itself- particularly the power transformer.

A blown fuse also provide a clue as to where a problem has occurred.

Fuses are not precision devices; they melt fairly slowly during faults,

taking many milliseconds to whole minutes to blow, depending on the level of overload.

In Europe there are two principle sorts of fuse to consider: time delay (T) and fast acting (F).

The similar equivalents in America are slow-blow and quick-blow.

Fuses used anywhere in a power supply will nearly always be of the time-delay/slow-blow type

since these can withstand a fair amount of inrush (surge) current when power is first applied and capacitors / transformers have to charge up.

Nevertheless, inrush will still cause the fusewire to flex, and after enough cycles it will inevitably fail due to fatigue.

This seems to happen every few years and is just fact of life,

although you can of course add an NTC thermistor to reduce inrush.

These days everybody uses 20 x 5mm cartridge fuses.

Don't waste your time with old-fashioned 32 x 6.3mm fuses in a new build.

The Primary Fuse

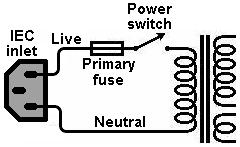

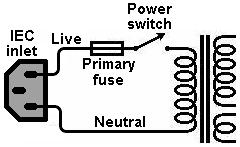

A fuse is series with the live wire where it enters the amp is absolutely mandatory.

This may be in a separate panel-mounted fuse holder or part of an IEC-inlet assembly.

This main fuse must be of the ceramic type, also called a high breaking capacity or HBC fuse.

These are filled with sand to dissipate heat and discourage vapourised metal from leaving a conductive path inside the cartridge,

so they can safely interrupt very large fault currents.

The fuse should be rated for around 1.5 to 2 times the normal primary operating current.

You can work this out by adding up the (maximum average) power used by each of the secondary widnings,

then divide by the mains voltage.

Whatever happens, the primary fuse must never be larger than the mains voltage divided by the transformer primary winding resistance.

1A is typical of most amps up to 60W.

Needless to say, it must also have a voltage rating suitable for use on the mains,

but this is no problem since most fuses are rated for mains use anyway.

A fuse is series with the live wire where it enters the amp is absolutely mandatory.

This may be in a separate panel-mounted fuse holder or part of an IEC-inlet assembly.

This main fuse must be of the ceramic type, also called a high breaking capacity or HBC fuse.

These are filled with sand to dissipate heat and discourage vapourised metal from leaving a conductive path inside the cartridge,

so they can safely interrupt very large fault currents.

The fuse should be rated for around 1.5 to 2 times the normal primary operating current.

You can work this out by adding up the (maximum average) power used by each of the secondary widnings,

then divide by the mains voltage.

Whatever happens, the primary fuse must never be larger than the mains voltage divided by the transformer primary winding resistance.

1A is typical of most amps up to 60W.

Needless to say, it must also have a voltage rating suitable for use on the mains,

but this is no problem since most fuses are rated for mains use anyway.

UK mains plugs also contain a fuse, but this is a crude last resort against serious fire hazards.

All amplifiers require a primary fuse, regardless of the plug fuse.

Secondary Fusing

The primary fuse is mainly there to prevent serious faults which may lead to overheating, fire or shock hazards;

it doesn't provide much protection for the components in the amp, even the power transformer.

Transformers may be quite big and robust,

but the sort of fault that can blow the primary fuse is often the sort of fault that can burn out a transformer winding first.

Most components in the amp are cheap and easily replaceable,

but the power transformer is valuable and deserves secondary protection.

A fully fused transformer should last longer than you do.

The primary fuse is mainly there to prevent serious faults which may lead to overheating, fire or shock hazards;

it doesn't provide much protection for the components in the amp, even the power transformer.

Transformers may be quite big and robust,

but the sort of fault that can blow the primary fuse is often the sort of fault that can burn out a transformer winding first.

Most components in the amp are cheap and easily replaceable,

but the power transformer is valuable and deserves secondary protection.

A fully fused transformer should last longer than you do.

Most valve-amp transformers have two windings: high voltage (HT or B+), and heater supply.

At the very least, the HT winding should have its own fuse.

Secondary fuses can be of the glass type (non HBC) since fault currents are greatly limited by the transformer itself.

A secondary fuse is normally rated for around 2 to 3 times the rated transformer current,

unless the transformer is capable of a lot more current than you're actually using,

in which case you may want to use a smaller fuse, more appropriate to the load current.

On vintage amplifiers the HT fuse is usually accessible via a panel-mounted fuse holder on the back of the chassis.

In modern amps all secondary fuses are likely to be hidden inside the chassis

so you can't stick your finger into the fuse holder and sue the manufacturer when you get a shock.

Fuse Positioning

When a fuse melts, an arc will be sustained until the gap widens enough to quench it,

or until the voltage drops to the point where the arc cannot be sustained.

With AC this happens very quickly since the voltage is continually passing through zero,

but with DC the arc will be sustained for much longer.

In other words, it is easier and safer to interrupt AC than DC.

Therefore, the fuse should always be placed in the AC part of the circuit, before the rectifier, where possible.

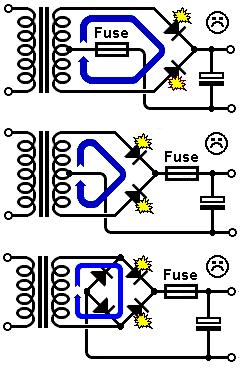

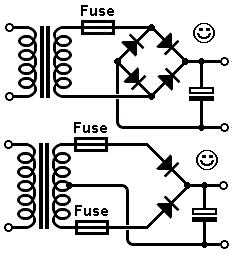

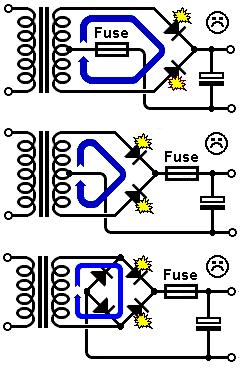

Traditionally, most valves amps use a two-phase rectifier and a single HT fuse.

Unfortunately, this doesn't protect the transformer against one of the most common faults:

shorted rectifier diodes.

The blue arrows in the image illustrate how fault current can flow,

bypassing the fuse and burning out the transformer.

The same is true for a bridge rectifier if the fuse is placed after the rectifier.

Silicon diodes commonly fail short, and even valve rectifiers do sometimes.

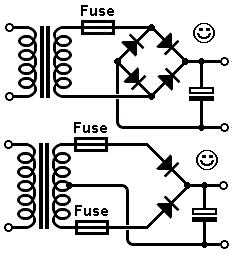

A two phase (centre taped) transformer therefore needs two fuses, one in each leg, to be safe from this sort of fault.

A bridge rectifier only needs one fuse, but it must be on the AC side (where it belongs anyway).

If you don't have the luxury of PCB or chassis-mounted fuse holders, then a convenient alternative is inline fuse holders.

You can see two in the photo, guarding a two-phase transformer.

Traditionally, most valves amps use a two-phase rectifier and a single HT fuse.

Unfortunately, this doesn't protect the transformer against one of the most common faults:

shorted rectifier diodes.

The blue arrows in the image illustrate how fault current can flow,

bypassing the fuse and burning out the transformer.

The same is true for a bridge rectifier if the fuse is placed after the rectifier.

Silicon diodes commonly fail short, and even valve rectifiers do sometimes.

A two phase (centre taped) transformer therefore needs two fuses, one in each leg, to be safe from this sort of fault.

A bridge rectifier only needs one fuse, but it must be on the AC side (where it belongs anyway).

If you don't have the luxury of PCB or chassis-mounted fuse holders, then a convenient alternative is inline fuse holders.

You can see two in the photo, guarding a two-phase transformer.

It is also important to consider what might happen to the rest of the circuit when a fuse blows.

For example, a blown fuse in the bias supply of a power output stage could lead to redplating and the destruction of the output valves.

Similar problems could occur in a DC-coupled amplifier if a heater-supply fuse blows.

This may require adding fast-acting/quick-blow fuses to other parts of the circuit to protect the valves against such calamities.

Fusing for the fuses...

Heater Fusing

An argument can be made for not fusing the heater winding, provided it supplies nothing but AC heaters and lamps.

You know, simple stuff.

There is very little to go wrong with a simple AC heater supply and the likelihood of a fault creating a permanent short is slim.

Also, the inrush to cold heaters at switch-on is so heavy that it may be difficult to find a fuse that will withstand it.

I've never seen a 20mm fuse rated at more than 10A. Beyond this you might consider automotive fuses.

Traditional amp designs don't use heater fuses, and I have never heard of it being a problem.

However, if the heater supply has a rectifier for DC heaters or ancillary circuits

then a fuse for the rectifier is strongly recommended, since diodes can fail short.

This fuse can be separate from the AC valve heaters, avoiding the problem of heater inrush.

|  A fuse is series with the live wire where it enters the amp is absolutely mandatory.

This may be in a separate panel-mounted fuse holder or part of an IEC-inlet assembly.

This main fuse must be of the ceramic type, also called a high breaking capacity or HBC fuse.

These are filled with sand to dissipate heat and discourage vapourised metal from leaving a conductive path inside the cartridge,

so they can safely interrupt very large fault currents.

The fuse should be rated for around 1.5 to 2 times the normal primary operating current.

You can work this out by adding up the (maximum average) power used by each of the secondary widnings,

then divide by the mains voltage.

Whatever happens, the primary fuse must never be larger than the mains voltage divided by the transformer primary winding resistance.

1A is typical of most amps up to 60W.

Needless to say, it must also have a voltage rating suitable for use on the mains,

but this is no problem since most fuses are rated for mains use anyway.

A fuse is series with the live wire where it enters the amp is absolutely mandatory.

This may be in a separate panel-mounted fuse holder or part of an IEC-inlet assembly.

This main fuse must be of the ceramic type, also called a high breaking capacity or HBC fuse.

These are filled with sand to dissipate heat and discourage vapourised metal from leaving a conductive path inside the cartridge,

so they can safely interrupt very large fault currents.

The fuse should be rated for around 1.5 to 2 times the normal primary operating current.

You can work this out by adding up the (maximum average) power used by each of the secondary widnings,

then divide by the mains voltage.

Whatever happens, the primary fuse must never be larger than the mains voltage divided by the transformer primary winding resistance.

1A is typical of most amps up to 60W.

Needless to say, it must also have a voltage rating suitable for use on the mains,

but this is no problem since most fuses are rated for mains use anyway.

The primary fuse is mainly there to prevent serious faults which may lead to overheating, fire or shock hazards;

it doesn't provide much protection for the components in the amp, even the power transformer.

Transformers may be quite big and robust,

but the sort of fault that can blow the primary fuse is often the sort of fault that can burn out a transformer winding first.

Most components in the amp are cheap and easily replaceable,

but the power transformer is valuable and deserves secondary protection.

A fully fused transformer should last longer than you do.

The primary fuse is mainly there to prevent serious faults which may lead to overheating, fire or shock hazards;

it doesn't provide much protection for the components in the amp, even the power transformer.

Transformers may be quite big and robust,

but the sort of fault that can blow the primary fuse is often the sort of fault that can burn out a transformer winding first.

Most components in the amp are cheap and easily replaceable,

but the power transformer is valuable and deserves secondary protection.

A fully fused transformer should last longer than you do.

Traditionally, most valves amps use a two-phase rectifier and a single HT fuse.

Unfortunately, this doesn't protect the transformer against one of the most common faults:

shorted rectifier diodes.

The blue arrows in the image illustrate how fault current can flow,

bypassing the fuse and burning out the transformer.

The same is true for a bridge rectifier if the fuse is placed after the rectifier.

Silicon diodes commonly fail short, and even valve rectifiers do sometimes.

A two phase (centre taped) transformer therefore needs two fuses, one in each leg, to be safe from this sort of fault.

A bridge rectifier only needs one fuse, but it must be on the AC side (where it belongs anyway).

If you don't have the luxury of PCB or chassis-mounted fuse holders, then a convenient alternative is inline fuse holders.

You can see two in the photo, guarding a two-phase transformer.

Traditionally, most valves amps use a two-phase rectifier and a single HT fuse.

Unfortunately, this doesn't protect the transformer against one of the most common faults:

shorted rectifier diodes.

The blue arrows in the image illustrate how fault current can flow,

bypassing the fuse and burning out the transformer.

The same is true for a bridge rectifier if the fuse is placed after the rectifier.

Silicon diodes commonly fail short, and even valve rectifiers do sometimes.

A two phase (centre taped) transformer therefore needs two fuses, one in each leg, to be safe from this sort of fault.

A bridge rectifier only needs one fuse, but it must be on the AC side (where it belongs anyway).

If you don't have the luxury of PCB or chassis-mounted fuse holders, then a convenient alternative is inline fuse holders.

You can see two in the photo, guarding a two-phase transformer.